Think

Bigger.

Otto Systems' new HOD-Series is the world's first high-performance preform production system engineered specifically for the rapidly growing Home and Office Delivery (HOD) drinking water market segment.

Revolutionizing HOD Preform Production

The production and availability of economical and sustainable 5- to 20-litre Home and Office Delivery (HOD) drinking water containers is a growing challenge for the food and beverage industry. Today's production lines only offer conventional solutions that fail to master the specific difficulties of economically producing the bigger HOD preforms. But now the Swiss engineers at Otto Systems have come up with a new product-specific solution that meets the requirements of this application in every respect.

Costly materials wastage, high energy consumption and lost time are now things of the past for HOD preform producers.

Key Features of Otto Systems' HOD Preform Production Solution

The new HOD-Series from Otto Systems has been developed with an uncompromising focus on the economical and high-quality production of HOD preforms. The HOD-Series from Otto Systems now meets all the demanding technical requirements in this field with a 160 and 240-ton-system.

1.

Otto Systems uses a unique outward moving toggle design with an extended stroke for larger preforms. Now, preforms up to 400 millimeters in length, commonly used for HOD containers, with can be efficiently produced.

2.

The fully integrated robot and post-mould-cooling systems with up to four positions offer the fastest cycle times and highest output quantities, even for such demanding applications.

3.

Otto Systems’ innovations offer HOD container producers an efficient, high-quality, high-output production system with low initial investment costs and reduced energy consumption in a well-engineered package that requires minimal floor space.

4.

Otto Systems’ HOD-Series was designed with maximum flexibility in mind from the start. This means that any standard preform application can easily be run on the same system configuration.

Jean-Claude Flückiger

Head of Operations Support

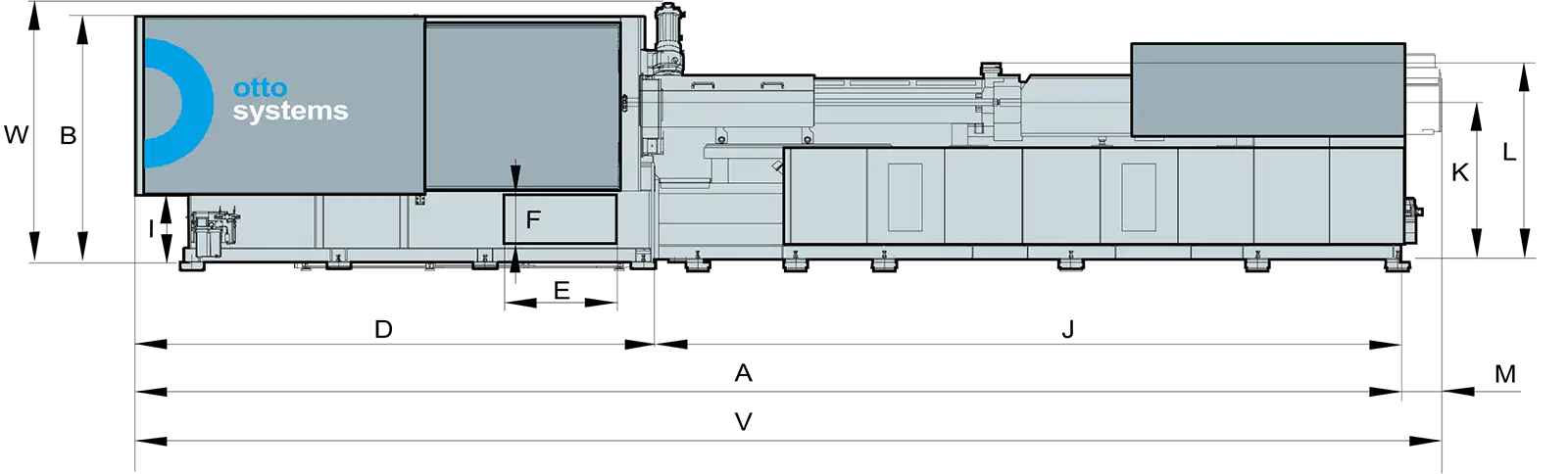

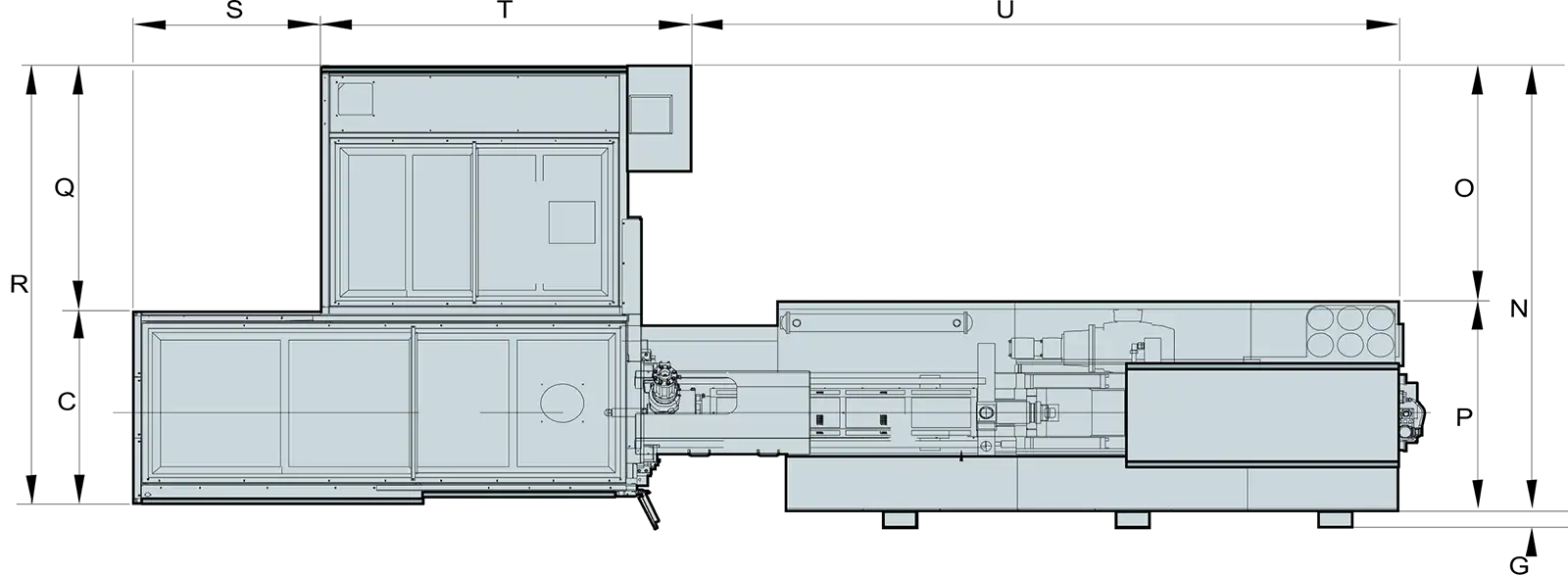

Dimensions of the HOD-Series 160

Technical Data

Lenght [mm]

Jump-start your preform production for HOD containers with an uncompromising, tailor-made HOD container production system from Otto Systems.

THINK BIGGER: Get in touch with us and learn more about how you can profit from Otto Systems’ new HOD-Series.

CONTACT US